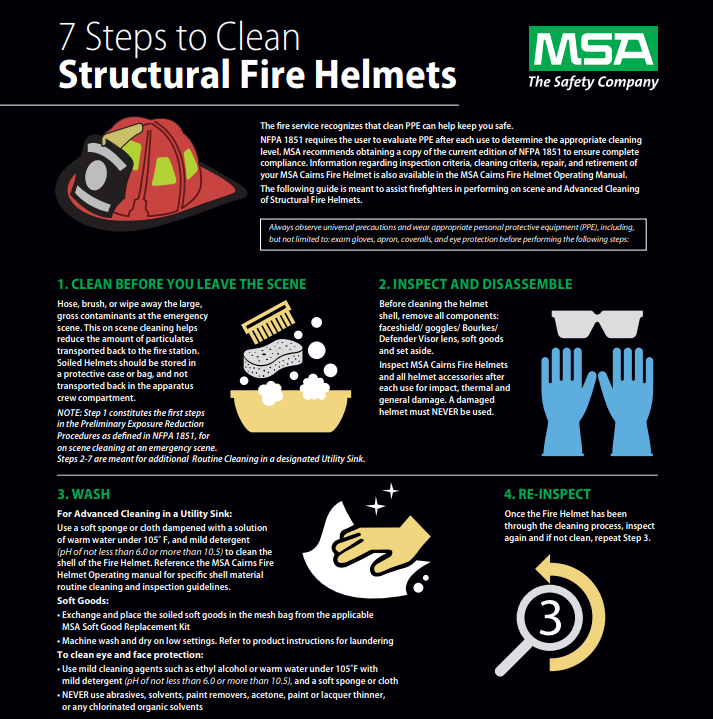

The fire service recognizes that clean PPE can help keep you safe. NFPA 1851 requires the user to evaluate PPE after each use to determine the appropriate cleaning level. MSA recommends obtaining a copy of the current edition of NFPA 1851 to ensure complete compliance. Information regarding inspection criteria, cleaning criteria, repair, and retirement of your MSA Cairns® Fire Helmet is also available in the MSA Cairns® Fire Helmet Operating Manual.

The following guide is meant to assist firefighters in performing on-scene and Advanced Cleaning of Structural Fire Helmets. Follow these seven steps to clean your structural fire helmet:

1. Clean before you leave the scene

- Hose, brush, or wipe away the large, gross contaminants at the emergency scene. This on-scene cleaning helps reduce the amount of particulates transported back to the fire station. Soiled Helmets should be stored in a protective case or bag, and not transported back in the apparatus crew compartment.

- NOTE: Step 1 constitutes the first steps in the Preliminary Exposure Reduction Procedures as defined in NFPA 1851, for on-scene cleaning at an emergency scene. Steps 2-7 are meant for additional Routine Cleaning in a designated Utility Sink.

2. Inspect and disassemble

- Before cleaning the helmet shell, remove all components: faceshield/goggles/Bourkes/Defender® Visor lens, soft goods and set aside.

- Inspect MSA Cairns® Fire Helmets and all helmet accessories after each use for impact, thermal and general damage. A damaged helmet must NEVER be used.

3. Wash

- For Advanced Cleaning in a Utility Sink: Use a soft sponge or cloth dampened with a solution of warm water under 105˚ F, and mild detergent (pH of not less than 6.0 or more than 10.5) to clean the shell of the Fire Helmet. Reference the MSA Cairns® Fire Helmet Operating Manual for specific shell material routine cleaning and inspection guidelines.

Soft goods:

- Exchange and place the soiled soft goods in the mesh bag from the applicable MSA Soft Good Replacement Kit.

- Machine wash and dry on low settings. Refer to product instructions for laundering.

To clean eye and face protection:

- Use mild cleaning agents such as ethyl alcohol or warm water under 105˚F with mild detergent (pH of not less than 6.0 or more than 10.5), and a soft sponge or cloth.

- NEVER use abrasives, solvents, paint removers, acetone, paint or lacquer thinner, or any chlorinated organic solvents.

4. Re-inspect

- Once the Fire Helmet has been through the cleaning process, inspect again and if not clean, repeat Step 3.

5. Drying

- Dry the Fire Helmet in an area with good ventilation; never dry in direct sunlight. Fire Helmets should never be machine dried using equipment that produces mechanical action by tumbling or agitation. Fire helmets and all components should be thoroughly dry before returning to service.

6. Storage

- Store clean Fire Helmets in a dry, well-ventilated area out of direct sunlight and away from indoor light sources, which can also produce harmful UV rays.

- Do not store in extreme hot or cold temperatures.

7. Record keeping

- Organizations should have a system for keeping minimal records for their MSA Cairns® Fire Helmets. To aid with record keeping guidelines, MSA has created an easy-to-use Fire Helmet Tracking Form (ID 3600-46), and the NFPA 1851, 2014 Edition – Compliance Guide for Cairns Fire Helmets (ID 3600-45-MC).

Download this one-page Cairns® Structural Fire Helmet cleaning guide. Easy to print and reference when needed!

Download our 7 Steps to Clean Structural Fire Helmets guide for you and your team!

Download the Guide